Centrifugal clutches

Smooth power transmission – Since 1982

Welcome to AMSBECK

Our in-house development, production, and sales processes provide streamlined pathways, swift decision-making, and maximum flexibility tailored to your needs. You are our top priority!

Amsbeck Maschinentechnik GmbH is a family-owned business and a globally recognized leader in manufacturing customized drive solutions, specializing in centrifugal clutches, centrifugal brakes, shifting clutches, push-on gears, and flange-connection gears.

In addition to our well-known products, we are happy to create a tailored solution for you in the field of drive technology.

Explore our centrifugal clutches and feel free to contact us.

We provide a wide

applications for centrifugal clutches

Experts in the industry of centrifugal clutches

Strong reasons to choose Amsbeck

Load-free start-up enabled by centrifugal clutches

Product characteristics of the centrifugal clutches

Are you in need of a centrifugal clutch for your application? At Amsbeck, we have been manufacturing centrifugal clutches and centrifugal brakes since 1982. Below is an overview of the functionality and benefits of Amsbeck centrifugal clutches:

Centrifugal clutches function as soft start clutches or no-load starting clutches. This allows the motor to be started without a load or to operate in a no-load state. This feature is particularly advantageous for drives that require high starting torque. As a result, you can select an engine that is tailored to the regular operating speed instead of one designed for high startup torque. The outcome is a smaller, more cost-effective engine.

This allows the selection of an engine that is tailored to the normal operating speed instead of one designed for high startup torque. The result is a cost-effective engine.

Operating principle of the centrifugal clutch

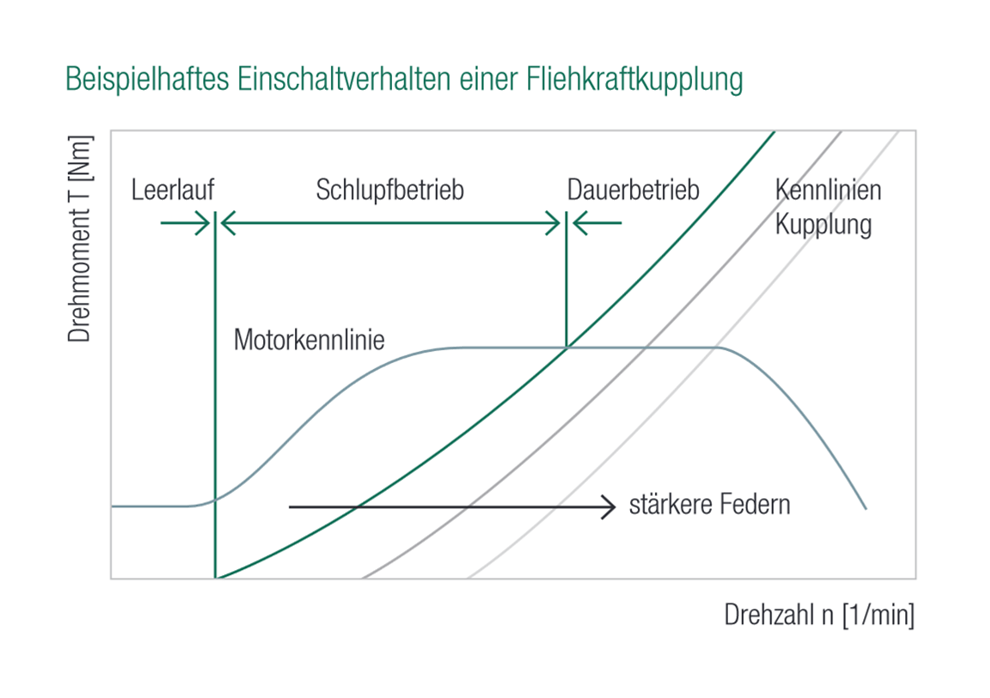

As soon as the weight elements of the centrifugal clutch are set in rotation, they experience a radial force component which accelerates them outward. This force of the centrifugal weights is compensated by the spring forces up to the defined engagement speed.

When the engagement speed is reached, the force of the centrifugal weights exceeds the restraining force of the springs and the friction linings come into contact with the housing of the centrifugal clutch. Torque begints to build up on the housing. The clutch is in slip mode and the application is accelerated rotationally to rated speed. The increase in speed leads to quadratically increasing forces and thus to an increase in torque. Once the nominal speed of the application is reached, the slipping operation ends and the torque is transmitted frictionally.

By varying the springs, the friction material, the size, the number of parallel elements and the operating speed, the engagement speed and torque are determined and adapted to the specific application.

Engaging of centrifugal clutch

The engagement speed of a centrifugal clutch is fundamentally influenced by the operating speed of the drive and the power it is required to transmit. Since the power transmitted by a centrifugal clutch increases quadratically with speed, a minimum operating speed for the drive system is essential.

The engagement speed refers to the point at which the centrifugal forces acting on the weights overcome the restraining force of the springs. By utilizing springs of varying strengths, which hold the centrifugal weights for different durations, the engagement speed can be adjusted. Choosing the appropriate springs allows for optimal tuning of the centrifugal clutch to meet the specific demands of the application.

Drawing on our extensive experience, we configure the engagement speed to ensure that a torque higher than necessary is achieved at the operating speed. This approach safeguards the clutch against slipping, even in the event of a brief reduction in speed.

Heat generation in centrifugal clutches

Friction produces heat, which means that during the slip phase, a centrifugal clutch converts friction work entirely into heat. Therefore, it is crucial to minimize the duration of slipping, as this is when the clutch experiences friction. The organic friction linings used by Amsbeck absorb only a small fraction of the heat generated. The majority of the heat is absorbed by the housing and surrounding components or dissipated into the environment through heat conduction.

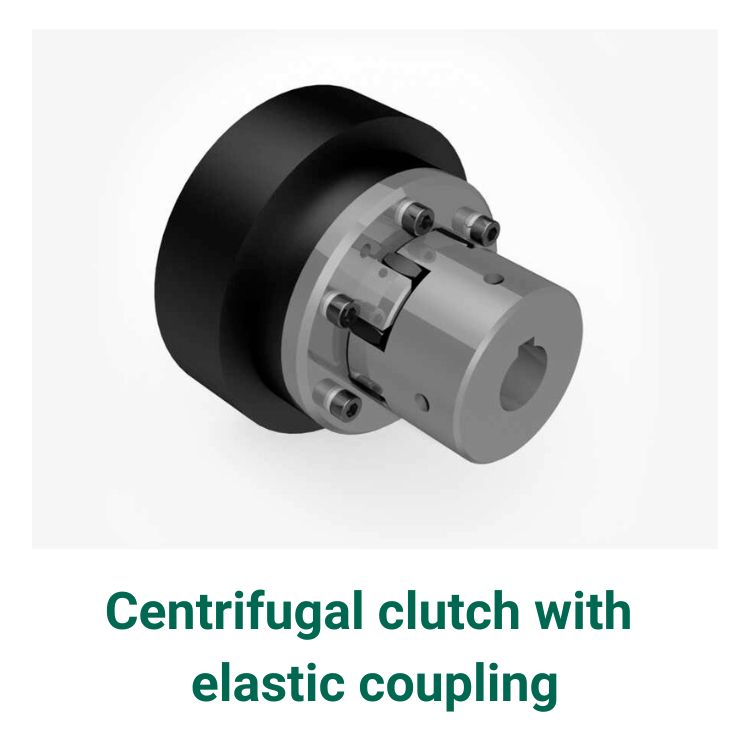

Types of constructions

There are various types of centrifugal clutches, but at Amsbeck, we primarily utilize two types that have proven effective over many years:

- Centrifugal clutch with free flyweights

- and centrifugal clutch with pivoting flyweights

In the basic version from Amsbeck, the centrifugal elements are mounted on the hub and guided via a “dovetail profile,” allowing for torque transmission independent of the direction of rotation. The torque support provided by the dovetail guide introduces a servo factor that depends on the angle of this guide, enhancing the torque transmission capability.

In the centrifugal clutch with pivoting flyweights, the centrifugal elements are guided with minimal backlash on one side by a pin at a pivot point. The solid carrier plate of the pins enhances the damping characteristics of the coupling, ensuring smooth and quiet operation in conjunction with the bearings of the centrifugal weights. Due to the self-reinforcing mechanism, similar to that of a duplex drum brake, very high torques can be achieved in one direction of rotation. However, in the opposite direction, the self-reinforcement is absent, resulting in a torque capacity reduction to approximately 50%.

Regardless of which design is best suited for your application or the type of engine you use, our couplings are customized to meet your specific requirements. Whether your engine shaft is keyed or tapered, we will tailor the coupling to fit your engine perfectly.

Applications for centrifugal clutches

Centrifugal clutches are utilized in various applications, including:

- Construction equipment

- Transport refrigeration units

- Sweepers

- Mowers

- Chainsaws

- Emergency generators

- Pump drives

- Lawn mowers

- Fans

- Kart racing

- Stump grinders

- Descenders

- Hydro and wind turbines

Would you like to determine if the principle of the centrifugal clutch is suitable for your application? Please feel free to reach out to us via phone, contact form, or email. Our team will be happy to collaborate with you on the technical design.

The direct line to our team

You can reach us

Monday through Thursday, 7:30 am to 4:30 pm,

and on Fridays from 7:30 am to 3 pm.

If you are looking for a specific drive concept, we recommend our product request form in which you can comfortably enter the necessary details.