Welcome to AMSBECK

Welcome to Amsbeck, a leading international manufacturer of in-house centrifugal clutches, proudly producing high-quality solutions since 1982. With over four decades of expertise, we have established ourselves as a trusted name in the industry, renowned for our commitment to innovation, quality, and customer satisfaction.

At Amsbeck, we understand that reliable performance is critical for our clients across various sectors. Our centrifugal clutches are designed to deliver exceptional efficiency and durability, meeting the rigorous demands of diverse applications, from automotive to industrial machinery. Our in-house production ensures that we maintain the highest standards of quality control, enabling us to consistently deliver products that exceed expectations.

Our dedicated team of engineers and technicians is at the heart of our success. We collaborate closely with our customers to understand their unique requirements, allowing us to create customized solutions that enhance their operational performance. Our focus on continuous improvement and innovation keeps us at the forefront of technological advancements in the industry.

The team that

provides drive in your application

Experts in the industry of centrifugal clutches

Strong reasons to choose Amsbeck

Driven by centrifugal forces!

Our team

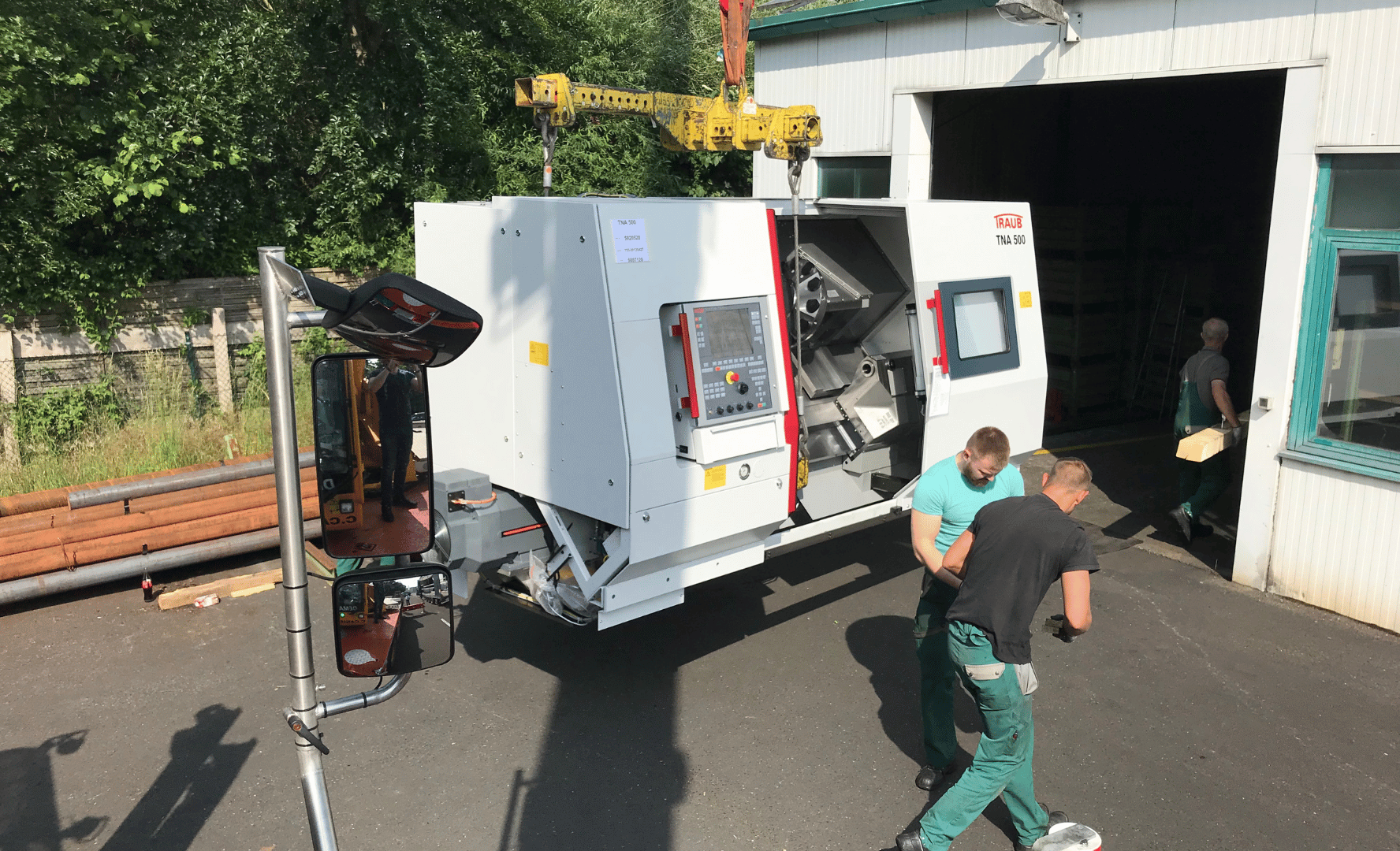

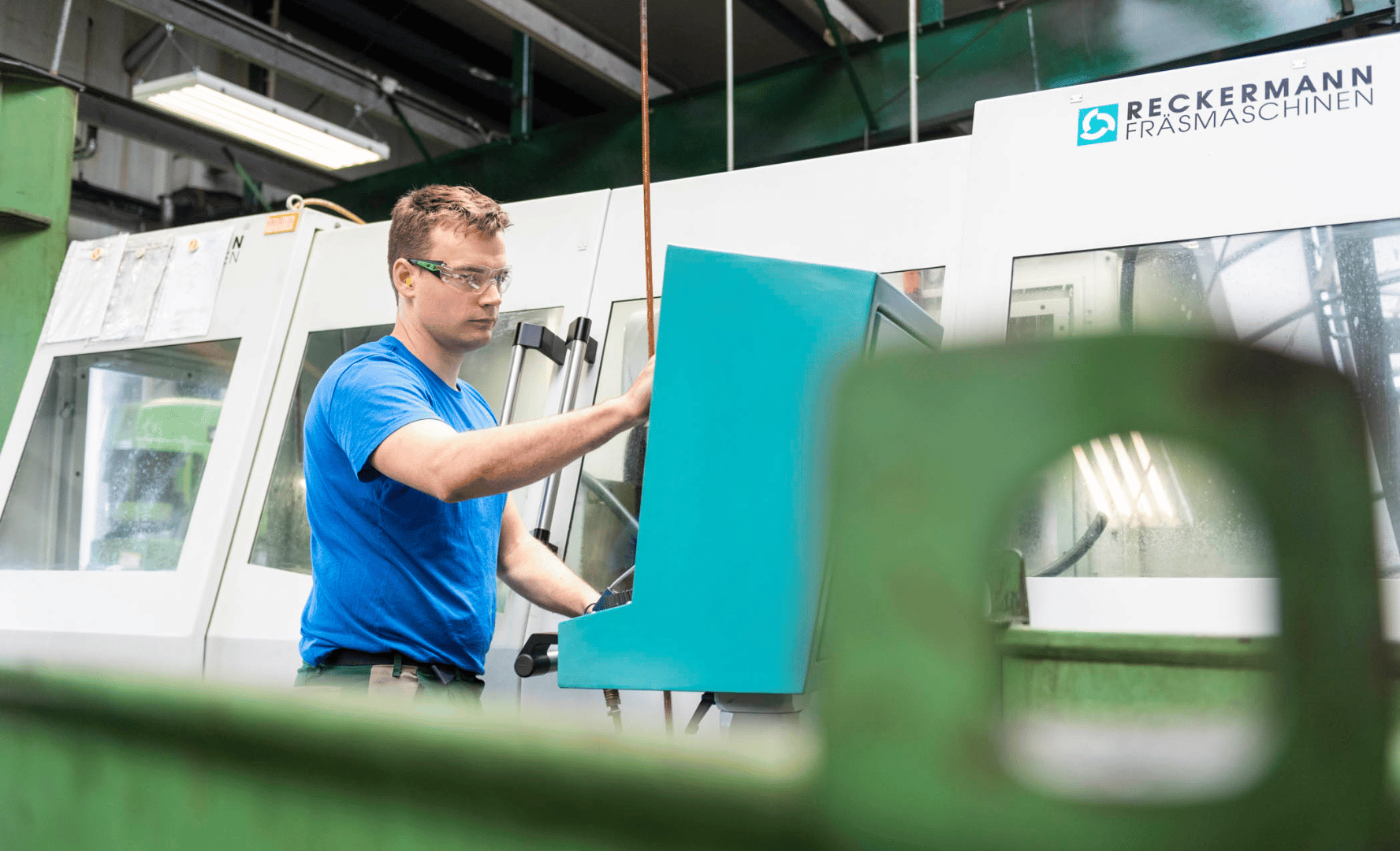

Our production and assembling

The requirements established during the development phase are executed with precision using advanced CNC machines. Our computer-aided manufacturing process guarantees optimal accuracy and fit, with human intervention limited to machine programming before production and quality control afterward. A significant advantage of our manufacturing capabilities is our flexibility in processing orders of varying sizes, enabling us to produce small batches and customized items on short notice, alongside our standard series production.

Our demands to quality and environmental protection

The direct line to our team

You can reach us

Monday through Thursday, 7:30 am to 4:30 pm,

and on Fridays from 7:30 am to 3 pm.

If you are looking for a specific drive concept, we recommend our product request form in which you can comfortably enter the necessary details.